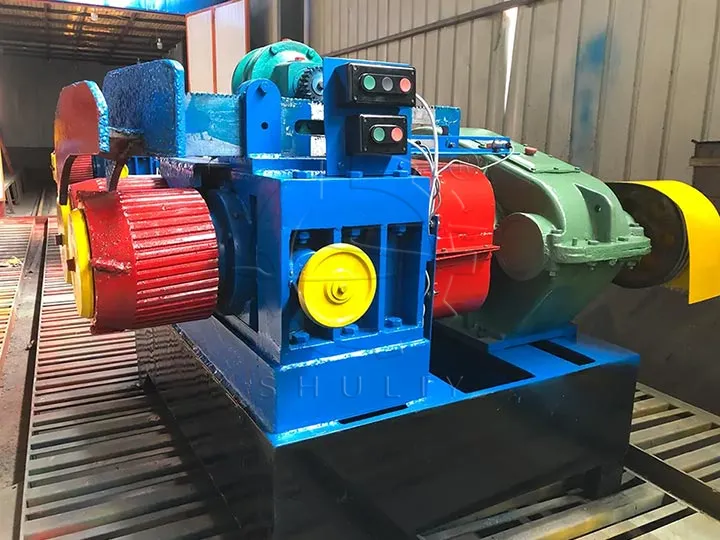

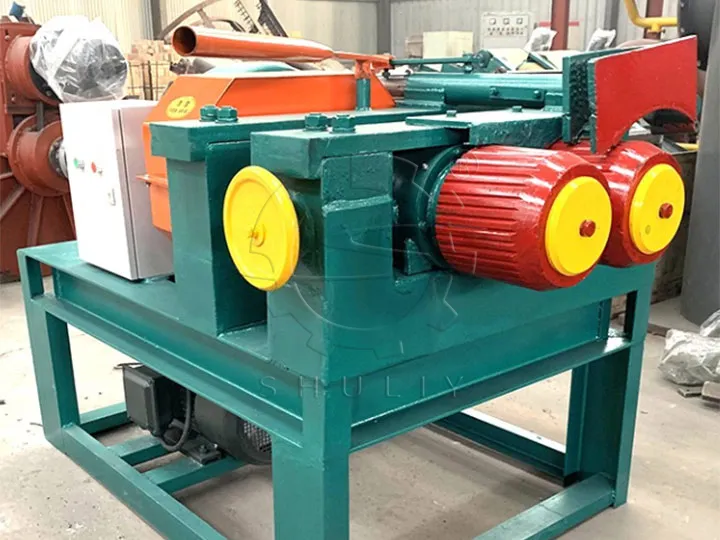

Tire Steel Wire Separator

The sidewalls cut by the tire ring cutter contain a large number of steel wires. the use of a tire steel wire separator can efficiently achieve the separation of rubber and steel bead, respectively, the recovery of rubber and steel wire, and improve the utilization rate of materials.

- Capacity: 120pcs/h

- Motor Power: 18.5KW

- Application: Separate steel wire and rubber from tire sidewalls

- सेवा: वारंटी, स्थापना, तकनीकी समर्थन आदि।

Key Features of the Tire Steel Wire Separator

Parameters of Tire Steel Wire Separator

| Model | SWS-100 steel wire separator |

| क्षमता | 120pcs/h |

| मोटर पावर | 18.5KW |

| Machine Weight | 1800kg |

| Machine Size | 2*1.9*1.8m |

How Does the Tire Wire Removal Machine Work?

The tire steel wire separator mainly includes: frame, two relatively rotating rollers, a motor and transmission system, a control system, inlet and outlet. It works as the following steps:

- Put the tire sidewall cut by the tire ring cutter between the two rollers.

- The two rollers rotate relative to each other at the same speed, and the rim is clamped into them for strong extrusion.

- The tire sidewall is squeezed, sheared, and torn between the rollers.

- Under the repeated rotation of the rollers, the gel is completely separated from the rim.

- Ultimately, the steel rim and rubber are completely separated, and the steel wire is discharged separately, which is convenient for subsequent processing or recycling.