How to Start Tyre Recycling in Nigeria?

Every day, approximately 250,000 used tires are discarded in Nigeria, with less than 10% being recycled. This results in both increasingly serious…

Every day, approximately 250,000 used tires are discarded in Nigeria, with less than 10% being recycled. This results in both increasingly serious environmental problems and huge business opportunities. The Federal Ministry of Environment and local governments are actively promoting the recycling industry, creating good opportunities for development in the Nigerian tire recycling industry.

So, how do tire recyclers look to start or grow tyre recycling in Nigeria?

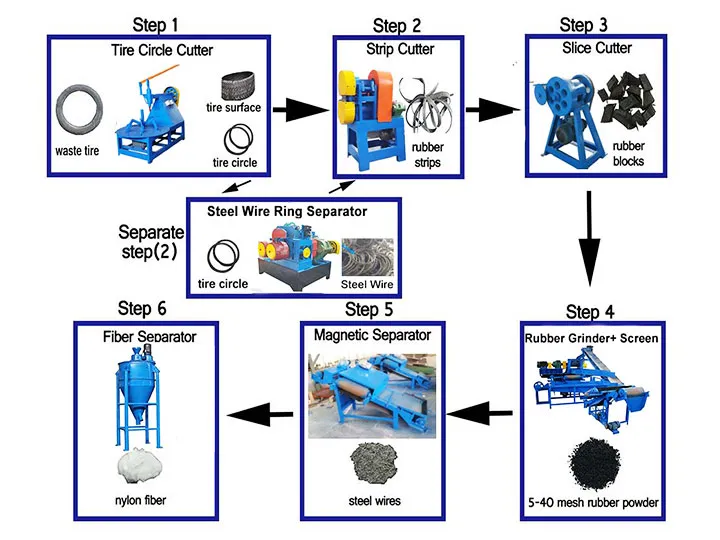

Tire Recycling Machinery for Start-ups

If you have a limited budget but want to start tyre recycling in Nigeria as soon as possible, these devices are a good place to start.

| Machine Name | Key Function | Recommended For |

|---|---|---|

| Tyre Sidewall Cutter | Cuts off both sidewalls of waste tyres, removing the steel bead | Startups, small tyre recycling companies in Nigeria |

| Tyre Strip Cutter | Slices tyre body into uniform rubber strips (3–5 cm wide) | Manual operators, entry-level tyre recyclers |

| Tyre Block Cutter | Cuts rubber strips into smaller rubber blocks for resale or further processing | Entrepreneurs that aiming to upgrade processing capacity. |

| Tire Steel Wire Separator | Pulls out high-strength steel wires from tyres for separate resale | Businesses seeking extra profit from steel recovery |

| Tyre Shredder (Optional) | Shreds rubber blocks into fine pieces for granule production | Small factories planning to produce rubber granules or mats |

Why Choose the Above Tire Recycling Equipment?

This equipment is part of our semi-automatic tire recycling line series, which is designed for start-ups and SMEs in the tire recycling industry. Its advantageous features are as follows:

Wide range of applications: Suitable for all waste tires up to 1200 mm in diameter, including car and truck tires, as well as other common types.

It adapts to the African industrial environment with its sturdy structure and high-temperature resistance, making it suitable for high-temperature and humid environments. It also has low power consumption and can operate continuously and stably.

Modular design allows for flexible expansion. Users can start with a single machine and gradually expand to a complete production line according to their needs, which reduces the initial investment pressure.

The environmentally friendly physical recovery process does not require high-temperature cracking and emits no pollution, aligning with local environmental policy guidance. Compared to the high-risk “pyrolysis refinery equipment” program, this program is safer and more reliable (several pyrolysis enterprises have been shut down in Lagos, which is a clear warning).

It has low investment costs and is more efficient to operate. The equipment is affordable, has low energy consumption, and has a small footprint. This significantly reduces operation and site costs and is suitable for small and medium-sized enterprises that want to start their projects quickly.

Key Profit Models for Tyre Recycling In Nigeria

How do you make a profit after the tyre recycling in Nigeria is completed?

1. Recycling of used tires → processing → sale of finished products

| Product | Target Buyers | Selling Price | Profit Source |

|---|---|---|---|

| 🔹 Rubber Chips | Cement factories, ECOWAS exporters | ₦22,000 – ₦28,000/ton | Used as alternative fuel (≥6,500 kcal/kg); cement plants mandated to reduce coal use (EPR Law 2023); 37% lower export tariffs within ECOWAS. |

| 🔹 Rubber Granules | Road contractors, sports floor builders, ECOWAS exporters | ₦110,000 – ₦130,000/ton | High-value product for asphalt and athletic surfaces; meets gov’t standard RN-4; eligible for ECOWAS tariff discount. |

| 🔹 Steel Wire | Scrap metal buyers, steel mills | ₦175,000 – ₦190,000/ton | High-strength steel; clean separation (≤0.3% rubber) earns up to 15% price premium; consistent market demand. |

| 🔹 Textile Fiber | Building material suppliers, acoustic insulation makers | ₦35,000 – ₦45,000/ton | Used in construction (Lagos GBS-2024 acoustic rule); 52% cheaper than imported fiberfill; emerging local demand. |

2. Provision of processing services. Processing services are provided to other scrap collectors for a “processing fee”.

3. Distribution or export of by-products. Enterprises that are in a position to do so can export the treated rubber granules and steel wires to Ghana and Cameroon after packing them to obtain exchange rate advantages.

Why Tyre Recycling in Nigeria is A Real Business Opportunity?

Tyre recycling in Nigeria is not just possible — it’s becoming increasingly profitable, thanks to supportive policies, abundant raw materials, and high product demand.

1. Government Incentives

Under the 2025 National Solid Waste Management Framework, tyre manufacturers and importers are now legally required to contribute to recycling costs — creating long-term funding channels for the sector. Meanwhile, Lagos State offers a 15% subsidy on tyre recycling equipment for registered operators, directly reducing startup investment pressure.

2. Low-Cost or Free Raw Materials

New environmental regulations require tyre retailers, service centers, and distributors to pay for the safe disposal of used tyres. As a result, many are handing over scrap tyres at zero or very low cost to licensed recyclers — giving your business a steady, low-risk supply stream.

3. Strong Market Demand for Recycled Products

Nigeria’s construction and infrastructure sectors are booming. Rubber granules are increasingly used in road asphalt, sports surfaces, and tile manufacturing. Steel extracted from tyres is in high demand from scrap metal processors. In many cases, supply still can’t meet demand — especially in regions outside Lagos and Abuja.

Combined, these factors create a recycling environment where entry barriers are low, but profit potential is high — especially for early movers equipped with reliable machines and a clear plan.

Let’s Build Your Tyre Recycling Business Together!

Whether you’re just exploring the market or ready to invest, we’re here to help. Our team has supported dozens of new recyclers across Africa with customized machine setups, site planning, and after-sales support.

✅ Send us your location and expected output

✅ We’ll recommend the right machines for your budget

✅ Start small, grow fast — and recycle smarter

Contact us today via WhatsApp: +86 17303831295!