Waste Tire Recycling Solution

For different types and sizes of tire powder production, Shuliy’s technical team has developed varying tire recycling solutions.

- Size of rubber powder: 5~100 mech;

- Purity of tire crumb rubber: More than 99%;

- Operation type: Semi-automatic/ fully-automatic;

- Types of tires can be processed: All kinds of tires, such as car tires, truck tires, bus tires, OTR mining tires, agricultural tires, etc.

- Service: Warranty, spare parts for free, on-site installation, technical support, etc.

Diversified Customized Tire Recycling Solutions

Through a variety of recycling solutions to efficiently process various types of scrap tires, the output particle size is between 5 to 100 mesh, pure rubber rate of 99% or more of high-quality rubber powder.

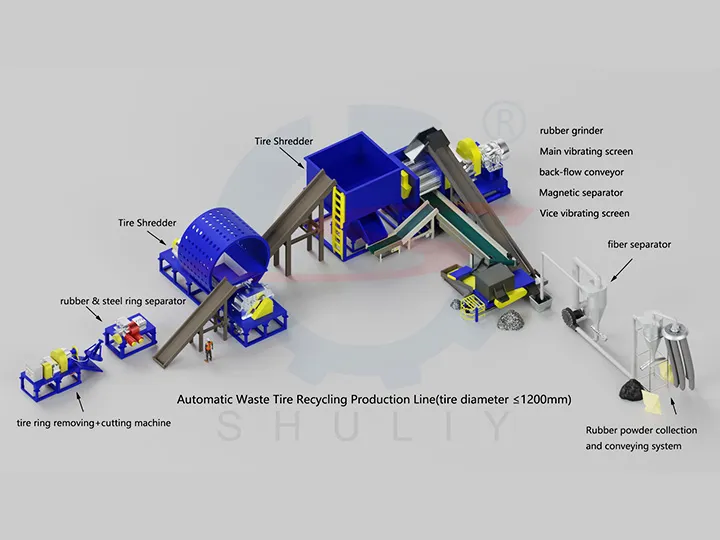

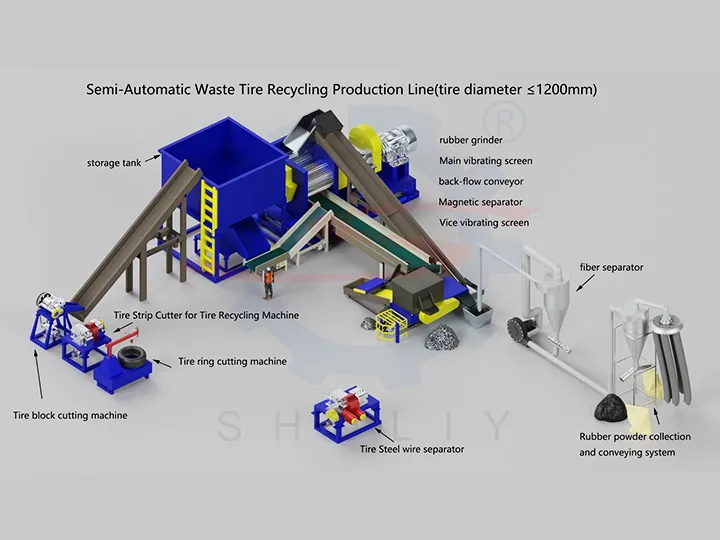

Semi-automatic Tire Recycling Line

Manual assistance to complete the tire recycling, low investment, suitable for small factories (tire diameter <1200 mm).

Features:

- Manual assistance, low cost;

- Simple structure, easy to operate and maintain;

- Suitable for smaller tire recycling plants.

Tire Recycling Steps

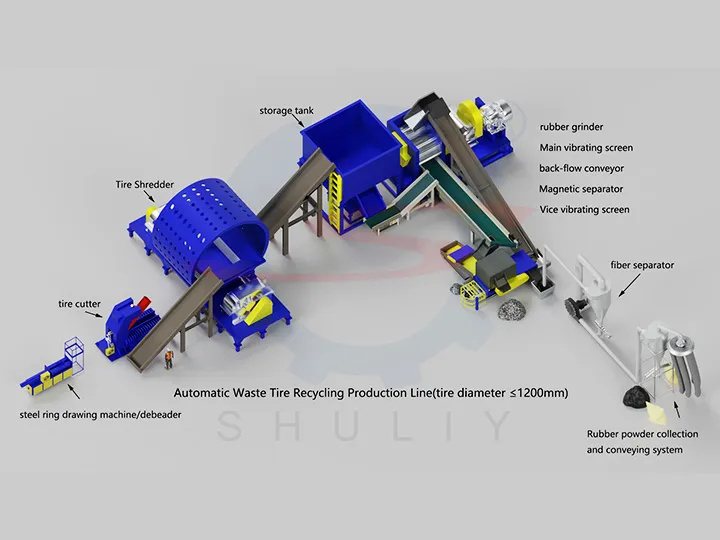

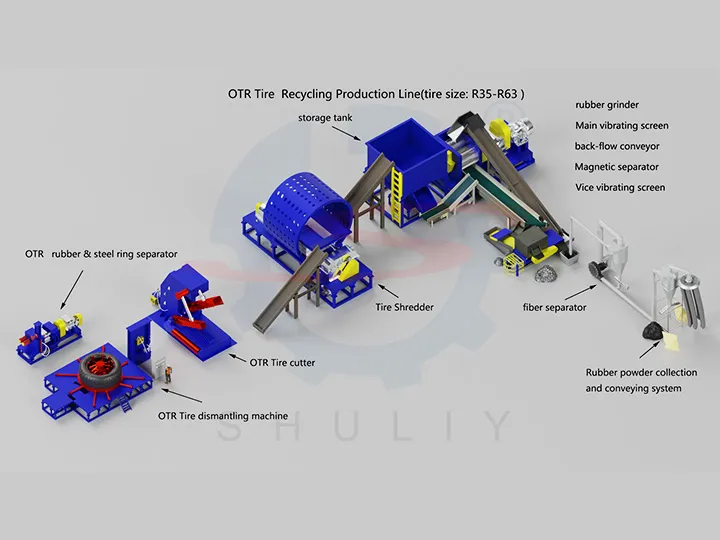

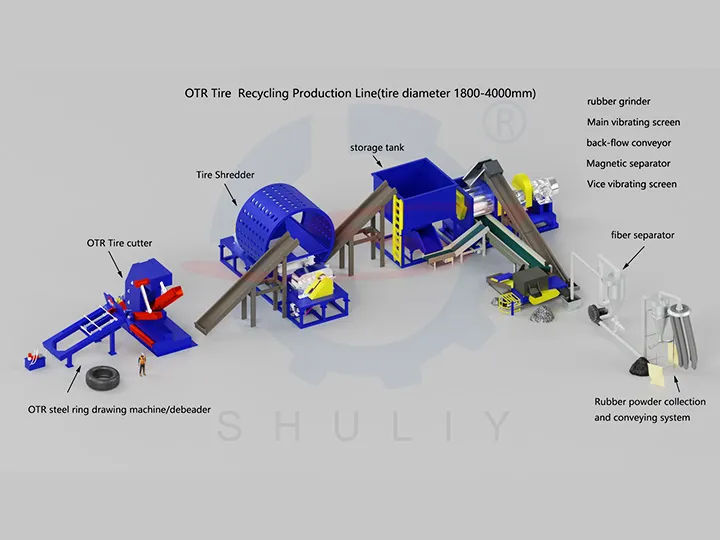

The production of high-quality rubber powder is a refined process, with the main stages including pre-treatment, shredding, grinding, and screening. For different types of scrap tires, the key differences in recycling solutions are usually reflected in the pre-treatment stage.

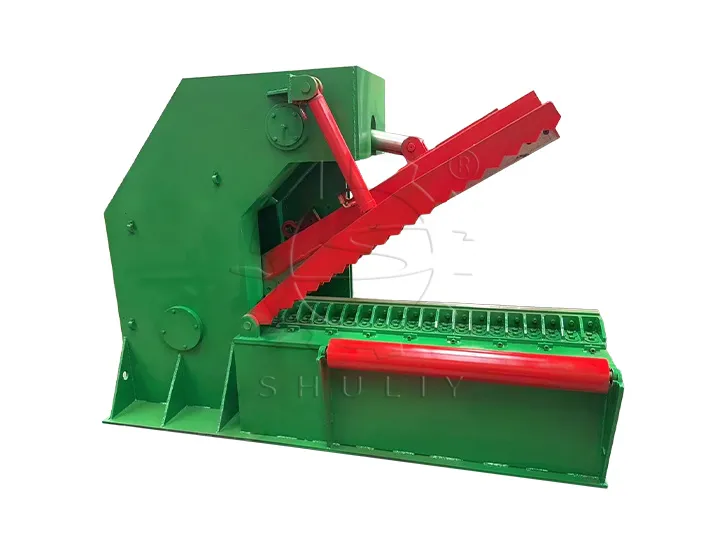

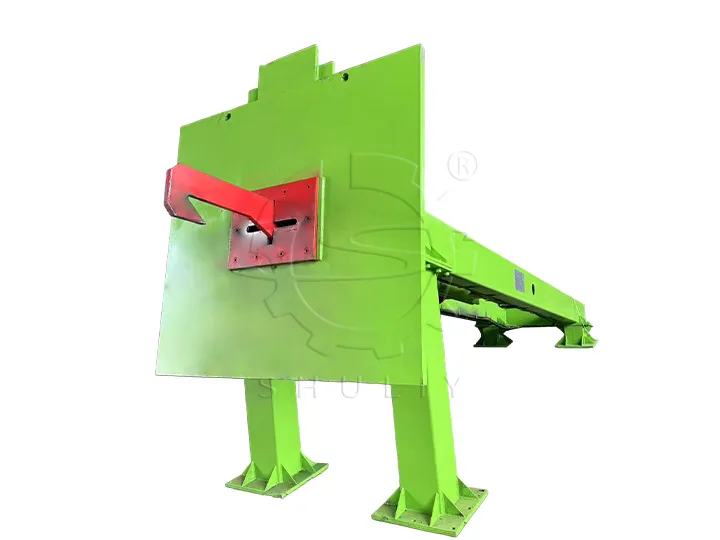

Step 1: Pre-treatment

Through the synergistic cooperation of all equipment, waste tires containing steel wires, nylon, and other impurities are converted into uniform rubber blocks that are easy to shred.

- Pretreat steps in Semi-Automatic Tire Recycling Line: Tire ring cutter, tire strip cutter, tire block cutter

- Fully Automatic Tire Recycling Line : Tire wire drawing machine, tire cutting machine

- Full Automatic tire powder production line: Tire bead cutting and removal machine

- OTR tire recycling line: OTR tire debeader, OTR tire cutter

- OTR tire recycling solution:OTR dismantling machine

Step 2: Shredding tires

Shredding rubber blocks into smaller pieces to improve the efficiency of rubber milling and recycling, while reducing the workload of the subsequent crumb rubber making machine.

- Model: SL-900/ SL-1000/ SL-1200/ SL-1500/ SL-1800

- Capacity: 2t/ 4t/ 5-6t/ 8-10t/ 15-20t pre hour

- End products size: 50 mm/ 60 mm/ 60 mm/ 75 mm/ 100mm

If you have other recycling needs. Please feel free to contact us for customized tire recycling solutions.

Step 3: Crushing and screening

Finally, a grinding and screening unit converts shredded rubber pieces into fine rubber powders that meet requirements, while also screening for nylon, magnetic, and other impurities.

- Composed machines: rubber grinder machine, fiber separator, magenic separator

- End rubber powder size: 10 mesh/ 20 mesh/ 30 mesh/ 40 mesh

- Capacity: 250-2300 kg/ 180-1700 kg/ 150-1300 kg/ 80-1000 kg per hour

For more machine details, please don’t hesitate to get in touch with us!

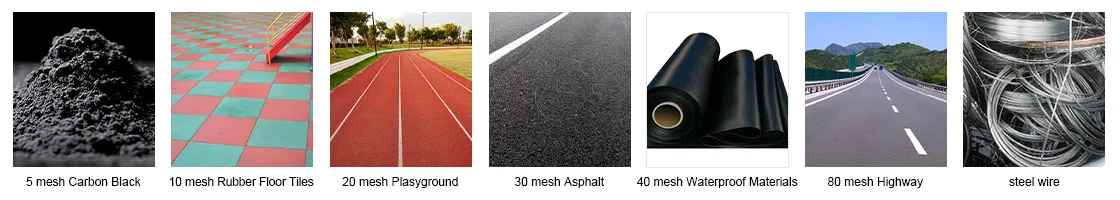

Applications of the End Products of Tire Recycling Machines

With the tire recycling equipment, you can efficiently achieve the separation and recycling of rubber, steel wire, nylon and other resources, and is widely used in the following areas

Frequently Asked Questions about Tire Powder Machines

If you want to learn more, please feel free to get in touch with us!