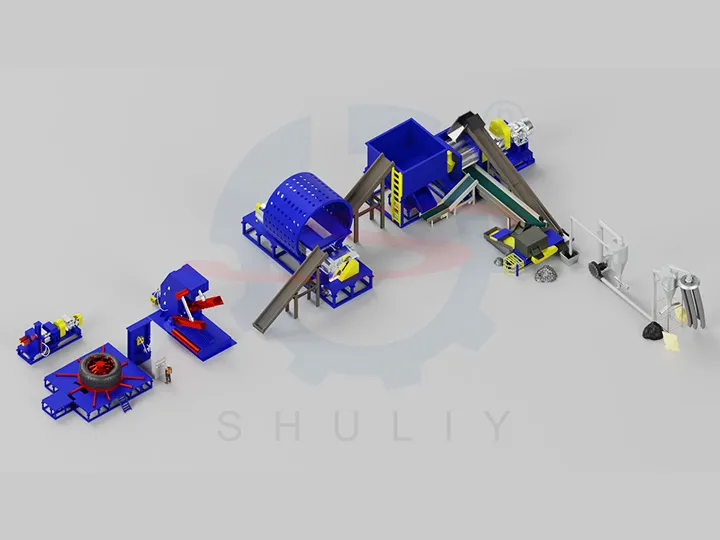

OTR Tire Recycling Machines

OTR tire recycling machines are designed to process large tires with a diameter of more than 1.8 meters, including: mining tires, earthmover tyres, agricultural tires, loader tires, etc.

- Raw Materials: OTR tires >1.8 m

- End Products: 5-40 mesh rubber powder

- Output Purity: More than 99%

- Operation Style: Fully automatic

What’s the Work Range of OTR Tire Recycling Machines?

OTR tire recycling equipment can be widely used in the following recycling scenarios:

- Mining industry: mining truck tires, giant dump truck tires, earthmover tires, etc.

- Agriculture: tractor, harvester tires, etc.

- Construction industry: excavator, loader, bulldozer tires, etc.

- Port logistics industry: large crane tires, etc.

For more applications, please contact us for details. The finished product of the mining tire recycling equipment is rubber granules or 5-40 mesh fine tire powder, which can be widely used in the production of recycled rubber products, modified asphalt, vibration-damping mats, and resilient flooring materials such as playground tracks.

In addition, valuable materials such as steel wires and nylon fibers contained in OTR tires can be effectively separated and recycled separately in the recycling process.

Key Features of Our Mining Tire Recycling Equipment

An OTR Tire Recycling Line Works in the Factory

Two Specialized Earthmover Tyre Recycling Solutions

To maximize the efficiency of OTR tire recycling machines, we offer two solutions for tires from 1.8 to 4 meters and 3.5 to 6.3 meters.

1.8-4 m OTR tire recycling line

Step 1: Remove steel rings

The OTR wire drawing machine directly pulls out the steel rings inside the mining tires through the powerful hydraulic system and traction system to improve the efficiency of rubber powder production.

- Capacity: 30 pcs/h

- Power: 22+3 KW

- Application: 1.8-4 m tires

Step 2: Cut rubber tires

Alloy steel blades are hard and durable, with strong cutting power, efficiently cutting giant tires into several segments

- Capacity: 120 cuts/h

- Power: 7.5 KW

- Blade material: Cr12MoV

- Application: 1.4-4 m tires

Step 3: Shred tires

Tire Shredders powerfully shred tires into easily grindable, uniform pieces of rubber. A wide range of models is available to recycle rubber efficiently.

- Model: SL-900/1000/1200/1500/1800

- Capacity: 2-20 t/h

- Power: 64.5-328.5 KW

- Output size: 50-100 mm

Step 4: Crushing and screening

The multi-stage process of magnetic separation, grinding, and screening ensures the purity of the final rubber granulate or powder, with adjustable stages and output size based on raw material characteristics and production needs.

- Output size: 5-40 mesh

- Capacity: 80-2300 kg/h

Step 1: Disintegrate the earthmover tyre

OTR dismantling machine cuts and separates engineering tires into 4-6 parts, such as bead, tread, top, etc., for further processing.

- Capacity: 7-15 min/tire

- Power: 7.5+5.5 KW

- Blade material: Tungsten steel alloy

- Application: 1.4-2 m tires/ R35-R63 OTR tires

Step 2: Separate the tire rim steel wires

Separate the steel wire in the bead mouth of the tire bead to realize the separation and recycling of resources.

- Capacity: 2-5 min/ tire bead

- Power: 35.5 KW

- Application: 1.4-4 m tires

- Machine size: 3.65*2.1*1.95 m

Step 3: Cut rubbers

Slicing all engineering tires that have been separated from the rim wire in the step 1 and 2. The old tire cutting machine features high efficiency and durability.

- Capacity: 120 cuts/h

- Power: 7.5 KW

- Blade material: Cr12MoV

- Application: 1.4-4 m tires

Step 4: Shred rubber tires

Shreds tire segments into smaller pieces for subsequent recycling. Powerful shredding with no jams and no downtime!

- Model: SL-900/1000/1200/1500/1800

- Capacity: 2-20 t/h

- Power: 64.5-328.5 KW

- Output size: 50-100 mm

Step 5: Scrap tyre powder making

The rubber powder crusher machine can process 30-100mm tire blocks into 5-40 mesh rubber powder and separate steel wire and nylon fiber during operation.

- Output size: 5-40 mesh

- Capacity: 80-2300 kg/h

Improve Your Mining Tire Recycling with Our OTR Tire Recycling Machines!

Shuliy OTR tire recycling machines are designed for giant tire recycling. With their robust construction and customizable configurations, they can be used in a wide range of applications. Please tell us your production needs, we’ll recommend the most suitable recycling solution for you, increasing both economic and environmental benefits!