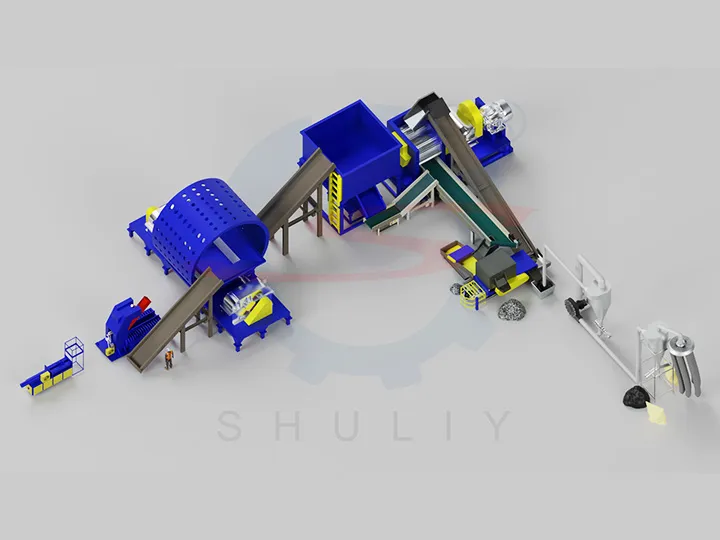

Fully Automatic Rubber Powder Production Line

The fully automatic rubber powder production line processes waste tires under 1200 mm in diameter with intelligent control and a modular design. It ensures efficient, safe, and standardized production, making it suitable for medium and large-scale tire recycling plants.

- Raw Materials: tires < 1200 mm

- End Products: Rubber powder ranges from 5 to 40 mesh

- Operation style: Full automatic

Application of Fully Automatic Rubber Powder Production Line

Our fully automatic rubber powder production lines can process scrap tires under 1200 mm in diameter, including those from cars, buses, trucks, etc. They enable efficient recycling and precise powder production, with adjustable fineness from 5 mesh to 40 mesh, which meets the production standards for modified asphalt, construction filling, rubber products, and more.

In addition, steel wire, nylon, and other materials can also be separated from tires for recycling.

Why Choose Shuliy Tire Crumb Rubber Machines?

Shuliy automatic tire recycling lines have been well-received by customers all over the world since their development. They features:

Working Video of the Fully Automatic Waste Tire Recycling Line

What’s the Working Process of Tire Recycling Production Line?

Shuliy offers a variety of fully automated tire recycling solutions to suit a wide range of rubber powder production needs, with the following three solutions being the most widely applicable.

Step 1: Removal of steel wire from waste tires

Single and double hook wire drawing machines are available for efficient removal of tire rims. Strong hydraulic system and solid equipment structure provide a good foundation for tire recycling

- Capacity: 20-50 tires/h

- Power: 11/18.5 KW

- Machine weight: 1400/1500 kg

Step 2: Cut rubber tires

Tire cutting machine is specially used to cut rubber tires into 2-3 pieces, which is convenient for subsequent shredding and grinding, and enhances the efficiency of tire recycling.

- Capacity: 60 tires/h

- Power: 7.5 KW

- Blade material: Cr12MoV

Step 3: Shred rubbers for grinding

The tire shredder uses a powerful shearing force to shred large tires into small, uniform pieces approximately 5 cm in length and width, providing a strong guarantee for the final production of rubber powder.

- Model: SL-900/1000/1200/1500/1800

- Capacity: 2-20 t/h

- Power: 64.5-328.5 KW

- Output size: 50-100 mm

Step 4: Grinding&screening

Effective separation and removal of impurities, such as magnets can be achieved through multi-stage processing, such as magnetic separation, grinding, and screening again. In addition, the particle size of the finished tire powder can be set freely.

- Output size: 5-40 mesh

- Capacity: 80-2300 kg/h

Step 1: Steel ring removal and cutting

Integrate the two functions of bead removal and tire cutting to efficiently realize the pre-processing of scrap tires, eliminating the intermediate material transfer steps and improving the processing efficiency and safety.

- Capacity: 3 t/h

- Power: 7.5+3 KW

- Blade material: Cr12MoV

Step 2: Separating rubber from cut tire

Separating the steel wire and the rubber portion of the cut tire bead in step 1 to achieve separate recycling processing of resources. Rubber is shredded in the next stage.

- Capacity: 120 pcs/h

- Motor power: 18.5 KW

Step 3: Shredding rubber tires

The finished tire blocks from step 1 are efficiently shredded together with the finished rubber from step 2. Various models are available, and the super power meets your production needs!

- Model: SL-900/1000/1200/1500/1800

- Capacity: 2-20 t/h

- Power: 64.5-328.5 KW

- Output size: 50-100 mm

Step 4: Crushing and Screening

Shredded tire blocks are processed through a fine grinding system to produce rubber powder, which is then graded and screened with a multi-layer mesh. This modular screening process allows for flexible adjustment of particle size based on application needs, ensuring stable product fineness.

- Output size: 5-40 mesh

- Capacity: 80-2300 kg/h

Our tire shredders provide a variety of capacity and power models to meet the needs of different processing scales. If you choose a high-power tire shredder, you can achieve direct shredding of whole tires, without pre-cutting and other pre-processing procedures, and you can efficiently enter the subsequent grinding recycling process.

Step 1: Shredding waste tires

The rubber tire chipper with strong shear force and stable structure can be widely used in standard tires, OTR tires, etc., to achieve comprehensive and efficient crushing.

- Model: SL-900/1000/1200/1500/1800

- Capacity: 2-20 t/h

- Power: 64.5-328.5 KW

- Output size: 50-100 mm

Step 2: Crumb rubber manufacturing

It can accurately classify the rubber powder and efficiently remove impurities to ensure the continuous and stable output of high-quality tire powder. The whole process is environmentally friendly and efficient, and can be flexibly controlled and adjusted.

- Output size: 5-40 mesh

- Capacity: 80-2300 kg/h

Get Your Customized Tyre Powder Production Line!

Shuliy’s fully automatic rubber powder production lines are known for their excellent quality, perfect after-sales service, and flexible and adjustable customized service. We sincerely welcome every partner to join us. Please don’t hesitate to contact us and send us your production situation, we will provide you with the most suitable solution for tire transfer!