Semi-Automatic Tire Recycling Line

High-quality, manual-assisted tire recycling line that converts scrap tires into recycled rubber granules, suitable for small, low-volume tire recyclers.

- Raw materials: Tires <1200 mm

- End products: Tire crumb rubber within 5-40 mesh

- Operation style: Machine operation + manual assistance

- Number of operators: 2-4 staff

Application of Semi-automatic Tire Recycling Line

The semi-automatic tire powder making machines are designed to process various types of waste tires with diameters of up to 1200mm. These machines efficiently produce high-quality rubber powder, facilitating resource reuse. The fineness of the rubber powder can be easily adjusted to meet different industry requirements, with a range of 5 mesh to 40 mesh available for reprocessing needs.

The recycled tire powders can be widely used in modified asphalt paving projects, sports ground rubber track, rubber products manufacturing, recycled rubber raw materials, and other fields, with good market adaptability and application value.

Key Features of Shuliy Crumb Rubber Making Machines

Choosing high-quality and cost-effective tire powder machines for your business is crucial. Our semi-automatic tire recycling line features:

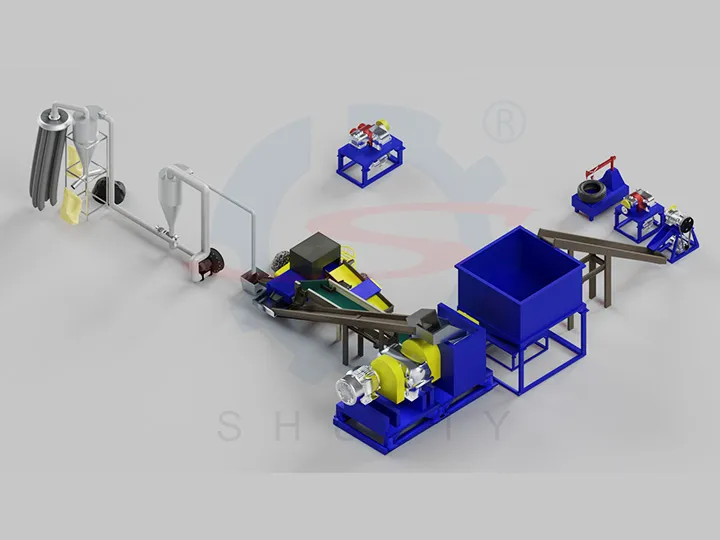

Workflow Overview of the Waste Tire Recycling Line

The entire tire rubber recycling plant has the following working process to make tire crumbs:

Waste tires→tire sidewall cutting machine→rubber tire removed steel wires→tire strip cutter→long rubber strips→tire block cutter→tire blocks→tire shredder→tire pieces→tire grinding&screening unit→fine rubber powders

Detailed Working Process of Semi-automatic Tire Recycling Production Line

Step 1: Cut the tire sidewall

Using a tire sidewall cutter to remove sidewalls with steel wires, resulting in rubber tires that can be easily recycled.

- Capacity: 40 pcs/h

- Motor power: 4+0.75 KW

- Application tires: 650-1250 mm tires

- Machine size: 1.8m*1.3m*1.6m

Step 2: Cut tyres into strips

Using a strip cutter, cut the rubber tires with the wire rims removed into 3-5cm wide strips for subsequent processing.

- Capacity: 1000 kg/h

- Motor power: 5.5 KW

- Motor speed: 45 r/min

- Machine size: 1.3m*0.8m*1.65m

Step 3: Turn rubber strips into blocks

Using a block cutter, long rubber strips 3-5 cm wide are efficiently cut into small pieces of about 5 cm in length and width.

- Capacity: 800-1500 kg/h

- Motor power: 5.5-18.5 KW

- Machine weight: 800-1200 kg

Step 4: Shred scrap tires into flakes

Use a tire shredder to cut tires into 50-100mm tire pieces. This crusher machine can be widely used for all kinds of tires with a powerful cutting force and durability.

- Capacity: 2-20 t/h

- Power: 64.5-328.5 KW

- Blade materials: composite alloy

- Fedding size: <1400mm

- Output size: 50-100 mm

Step 5: Crumb rubber manufacturing

The process involves several steps, such as grinding, screening, and demagnetization.

- Before entering the mill, the steel wire impurities are automatically separated by a magnetic separator.

- The tire pulverizer easily grinds tire pieces of 30-100mm into a fine powder.

- Through the physical screening effect of the screen, the rubber powder or granules of different sizes will be graded according to the output size, which can get 5-40 mesh of high-quality rubber powder.

Get Your Exclusive Tire Recycling Solution!

If you are looking to open or improve a small tire recycling plant, then the low investment, high return Shuliy semi-automatic tire recycling line would be a good choice. We promise:

- Free recycling program design

- Massive photo and video support

- High quality equipment with CE and ISO certification

- Smooth international logistics

- On-site installation and technical support

- One year free warranty

- Timely operation assitance!

Please don’t hesitate to get your exclusive tire recycling line, you can contact us via: