How Much Does it Cost to Start A Tire Recycling Business?

Tire recycling plants primarily convert waste tires into rubber blocks, granules, and powder, which are used in various manufacturing processes. Due to…

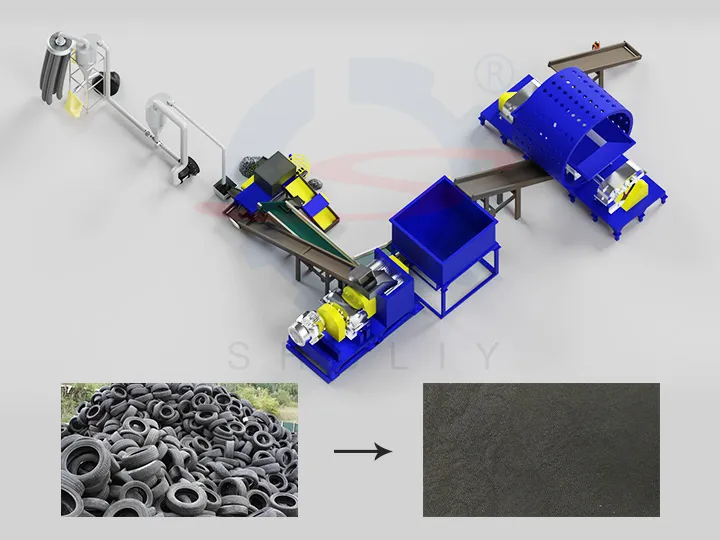

Tire recycling plants primarily convert waste tires into rubber blocks, granules, and powder, which are used in various manufacturing processes. Due to the growth of the automotive industry and the focus of governments on environmental protection, starting a tire recycling business can be both profitable and environmentally friendly. As a startup entrepreneur, it’s important to know the costs involved. Shuliy, an experienced tire recycling equipment supplier, provides a detailed guide and recommends its highly efficient recycling solutions to help you start your business quickly and at a lower cost!

Costs of Setting Up A Tire Recycling Business

First, understand the various costs involved, including:

- Equipment costs

- Site and operating costs

- Labor costs

- Purchasing and logistics costs

What Equipment is Needed for Tire Recycling?

Shuliy offers a variety of rubber manufacturing solutions for different recycling needs, each of which includes several models to choose from:

- For standard tires of 1200 mm or less, you can choose between semi-automatic and fully automated solutions.

- For large engineering tires with a diameter greater than 1200 mm, our exclusive OTR recycling solution can help improve the efficiency of your tire recycling business.

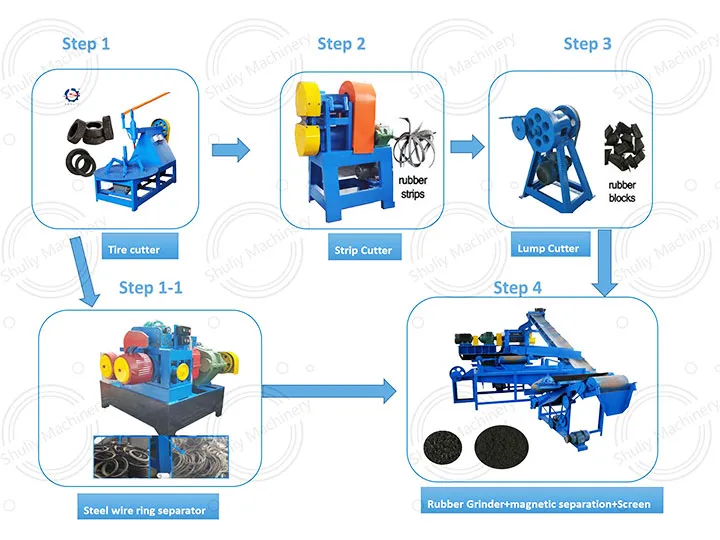

If you are a small—to medium-sized tire recycling entrepreneur, we recommend prioritizing investment in a Shuliy semi-automatic tire recycling line. This line offers lower costs, high efficiency, and high-quality rubber powder output. The complete line includes a tire ring cutter, tire strip cutter, tire block cutter, tire steel wire separator, tire grinder, magnetic separation machine, and fiber separator.

- The tire sidewall, strip, and block cutter are used to decompose tires gradually. They remove the steel wires from waste tires containing steel wires and fibers, and cut them into long strips and small, uniform pieces.

- The steel wire separator then separates the sidewalls cut by the tire ring cutter to obtain the steel wires and rubber. The rubber is then fed into the tire strip cutting machine for further processing. (Optional)

- The tire grinder and magnetic separator grind and sieve tire blocks to produce rubber powder with a purity of at least 99%, adjustable from 10 to 40 mesh.

- A fiber separator removes fibrous impurities from the tires further. (Optional)

The price of the corresponding tire line varies depending on the configuration, with prices starting as low as $24,490 for a complete line!

Analysis of Remaining Costs

- Land plant construction costs: need to be based on local rent, generally about 10,000 to 50,000 U.S. dollars

- Electricity and water costs: combined with the performance of the equipment, etc., generally about 2,000-15,000 U.S. dollars

- Labor costs: depending on the local job market, small tire factory needs about 2-4 people

- Freight: based on the distance of the country and the distance of the sea freight pricing, generally about 3,000-8,000

- Transportation cost: according to the country distance and sea distance pricing, generally about 3000-8000 US dollars.

Why Choose Shuliy As Your Partner?

As an experienced supplier of tire recycling machinery, Shuliy can provide sound and effective advice on starting your tire recycling business based on our many customer cases, saving you time and energy. Additionally, Shuliy’s tire recycling equipment is high-performing and easy to maintain. It is also designed to reduce operating and logistics costs.

Are you interested in starting a tire recycling business? If so, please do not hesitate to contact us! Let’s make this great green business happen together!