Shuliy Tire Recycling Plant Exported To Canada

Shuliy successfully sold the tire recycling plant to a crumb rubber manufacturer in Canada, enhancing their production efficiency, quality, and market competitiveness!…

Shuliy successfully sold the tire recycling plant to a crumb rubber manufacturer in Canada, enhancing their production efficiency, quality, and market competitiveness!

Background and Challenges of Our Client

This Canadian customer recycles scrap tires up to 1200mm in diameter to produce high-quality rubber floor tiles. Faced with aging equipment, inefficiencies, and high operating costs, the customer selected Shuliy’s fully automatic rubber powder production line to improve the existing rubber tile production process.

Why Choose Shuliy AS A Partner?

Shuliy’s Tire Recycling Solution Tailored To Client

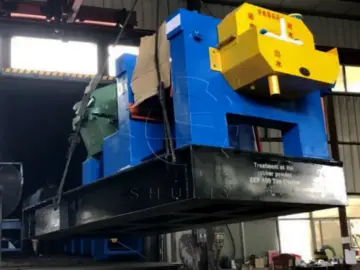

Our sales manager developed a customized tire recycling plant for the customer’s current problems and needs, offering a complete set of equipment for tire recycling and rubber tile production. This includes tire cutting, shredding, grinding, hot press molding, etc.

Tire Cutting and Shredding System

- Tire bead remover and cutter machine: Efficiently removes the steel wires from the tyre bead and cuts the remaining rubber into small, uniform pieces.

- 900# Tire shredding machine: Shred tire pieces into 3-8 cm size chips for subsequent milling with strong hydraulic systems.

- Feeding conveyors: Used to efficiently transfer materials between machines, saving labour and improving the efficiency of tire recycling!

Fine Rubber Grinding and Screening Unit

- SL-400 tire grinder: Double roller fine grinding of rubber blocks to 10-40 mesh, adjustable rubber powder with capacity up to 500 kg/h.

- Main vibrating screen and magnetic separator: Multi-stage screening to screen rubber powder to size and remove wire impurities.

- Fine magnetic separator and vibrating screen: A precision magnetic separator and sub-vibrating screen work together to thoroughly separate the steel wires, providing high-purity raw materials for the subsequent production of rubber floor tiles.

- Fiber separator: Fibres are removed by the principle of air-flow sorting, so that the purity of the rubber powder reaches more than 99%!

Rubber Tile Molding System

- Mixing and moulding machine: Mixes rubber granules with adhesive and performs high-temperature hot compression moulding.

- Suitable mould:

- 500×500mm (suitable for gymnasiums, sidewalks, etc.)

- 1000×1000mm (suitable for large plazas, playgrounds, etc.)

- Fully automatic PLC control press: realize automatic mould closing, suction, pressure maintenance, mould pushing and pulling and other operations, improve efficiency and reduce labour cost.

Feedback From this Canadian Client

Our tire recycling plant was successfully shipped via international logistics and installed on site by our engineers in Canada. The system was quickly up and running with excellent performance.

The customer commented: “The Shuliy tire recycling plant has significantly improved our rubber powder production efficiency while reducing labour and maintenance costs”.

Get Your Customized Tire Recycling Plant!

This perfect cooperation with a Canadian customer marks another success for Shuliy in the international tyre recycling market. If you are interested, please contact us for a customised solution!